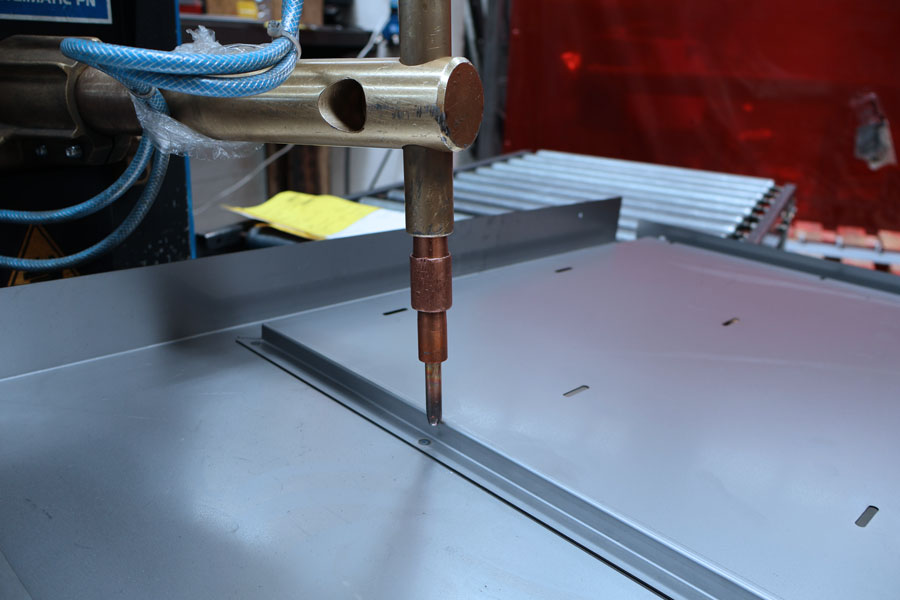

We also have a resistance welding station, or spot welding station, for joining sheets of up to 3 millimeters thick without the need for filler material.

This process is fast and efficient, allowing large quantities of metal parts to be joined in a short amount of time.

Additionally, it is a clean and precise technique, reducing the need for additional materials and minimizing the risk of defects in the parts.

Process

Resistance welding is a metal joining process that uses the application of electric current and pressure to melt and fuse the edges of metal pieces.

It is primarily used to weld conductive metals, such as carbon steel. During the process, the metal pieces are placed between two electrodes, and an electric current is applied through them, generating heat due to resistance. As pressure is applied, the edges melt and fuse together, creating a strong and permanent bond.

"Transforming Metals for Your Success"

We are leaders in the metal transformation sector, offering laser cutting, punching, tube laser, bending, and welding services. Quality and precision guaranteed!