Ricarte Metallic Transformations

SPECIALISTS IN METAL TRANSFORMATIONS: LASER CUTTING, PUNCHING, TUBE LASER, BENDING, AND WELDING

Laser Cutting

We have six state-of-the-art laser cutting cells with fiber technology up to 15kW, covering a thickness range from 0.5mm to 30mm in a 3,000×1,500mm format.

All machines are equipped with automatic material loading and unloading systems, optimizing the cutting process and operating in uninterrupted 24-hour cycles.

Tube cutting

Two 4 kW tube laser cutting machines with 3D heads for round, square, rectangular tubes, special profiles, and open profiles.

Punching

Two electric punching machines with automatic loading and unloading systems, featuring a cutting capacity of 2,500 x 1,250 mm.

Paneling

We have one paneling machine for automatic piece forming, eliminating the need for operator handling during the process.

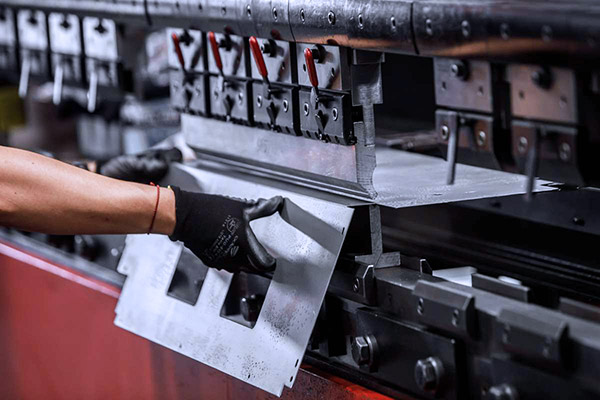

Bending

In our bending section, we have 14 automatic press brakes with a capacity of 220 tons and a bending length of 3 meters.

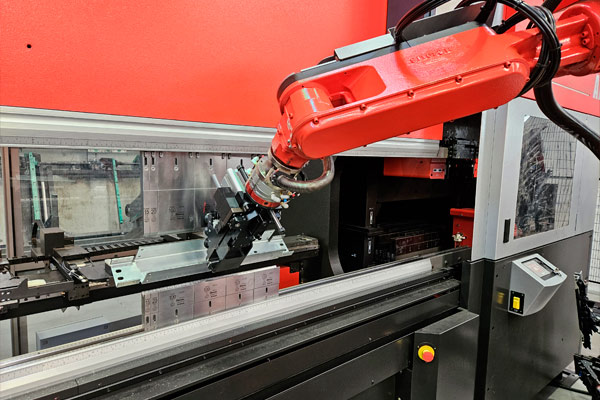

Robotic bending

Two robotic bending cells with which we achieve consistent precision, high productivity, and maximum safety. We are leaders in parts automation.

Welding

We offer manual MIG-MAG, TIG, and laser welding services for carbon steel and aluminum.

Welding robot

We have three welding robots, ideal for highly complex processes or projects with large production series. The automation of welding ensures greater efficiency and productivity.